ORDER NOW

CALL 800-827-7455 OR LOGIN TO YOUR ACCOUNT

JASPER UPDATES

- Cylinder heads are 100% inspected for cracks. The (Gen III & IV) head and head bolts are hydraulically clamped, which simulates head installation and allows cracked heads to be easily identified and discarded.

-

JASPER-designed pistons offer profiled ring lands for scuff resistance under load; increased strength to withstand higher combustion pressures; increased oil drain back to prevent the rings from sticking, and improved stability to reduce blow-by.

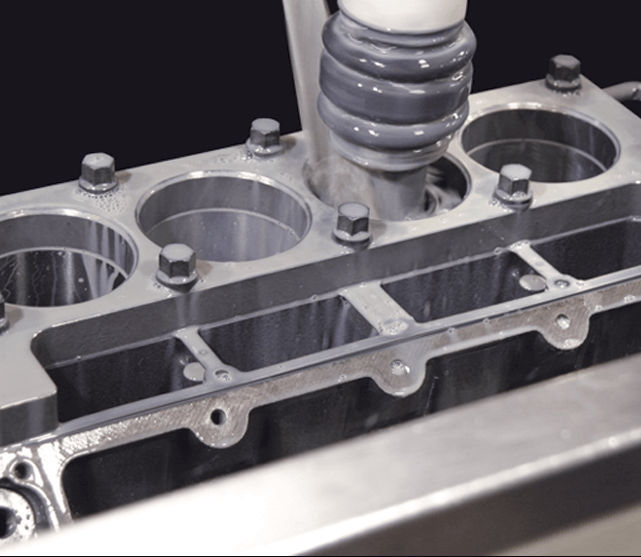

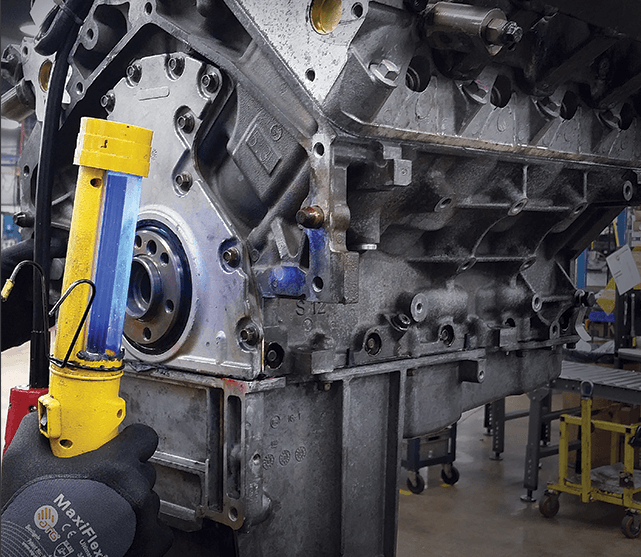

Torque Plate Honing

100% use of graphite-coated pistons prevent scuffing and wear; using tighter piston-to-bore clearance, JASPER prevents “cold piston slap” and oil consumption.

100% installation of an oil pressure relief valve baffle on all 2007 and later applications to redirect oil to the pan.

100% installation of nitrided valves to improve durability and reduce friction.

Latest-design Active Fuel Management (AFM) lifters are installed to increase oil flow during start-up and to reduce lifter noise (2005 - present).

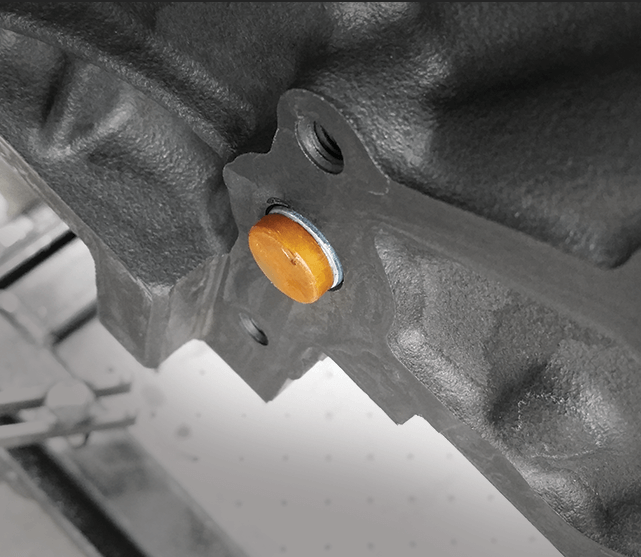

Block Oil Galley Plug

(Gen III & IV) 100% installation of the latest-design block oil galley plug to correct inconsistent oil flow and prevent low oil pressure.

Hydraulically installed cam bearings provide precise alignment, eliminating distortion of the bearings for improved oil flow and pressure.

(Gen III & IV) JASPER-remanufactured oil pump includes a more rigid spring, tighter clearance for backing plate flatness and is tested for increased oil pressure and flow.

(Gen III & IV) NEW exhaust manifold bolts are included.

100% Live-Run Testing, for your assurance of reliability, includes compression, vacuum, and oil pressure testing.

Black Light Leak Test

VVT cam phaser testing and/or AFM solenoid testing where applicable.

Black Light testing for leaks.

JASPER offers DOD/AFM Delete as an option for the 5.3, 6.0, and 6.2 engines.

DOD/AFM Delete will have a Non-DOD/AFM Cam, 16 standard lifters.

DOD/AFM Delete option is 50 state compliant (CARB E.O. D-391-2).

Tuner is included with all DOD/AFM engines.

NOW 50 STATE LEGAL CARB E.O.# D-391-2

Product Videos

GM Gen III & IV New Cam Bearing Installation

GM 5.3L Gen IV C/K/G Series Engine - Gen IV Piston Design Update

GM Gen V Cam Bearing Installation

GM Gen V Engine Piston Design

GM 5.3L Gen III & IV C/K/G Series Engine - Rocker Arm Inspection

GM 5.3L Gen III & IV C/K/G Series Engine - AFM Lifter Update

GM Gen III & IV Head Pressure Testing

GM V8 Gen III & IV

4.8 / 5.3 / 5.7 / 6.0 / 6.2

Value-Added Quality Improvements from JASPER

Issue / Concern:

Cracked Cylinder Heads Causing Coolant Loss

JASPER Solution:

-

JASPER uses a reverse torque sequence when removing head bolts to prevent cracks during disassembly.

-

Cylinder heads are 100% inspected for cracks. The head and head bolts are hydraulically clamped, which simulates head installation and allows cracked heads to be easily identified and discarded.

Piston Issues Causing Oil Consumption

-

JASPER-designed pistons offer profiled ring lands for scuff resistance under load; increased strength to withstand higher combustion pressures; and improved stability which reduces blow-by.

-

100% use of graphite-coated pistons to prevent scuffing and wear.

-

JASPER-designed pistons provide four times more oil drain back to prevent the rings from sticking.

Piston Slap On Cold Start

-

JASPER-designed pistons provide improved piston profile and through torque-plate honing, provides a tighter piston-to-cylinder wall clearance to prevent “cold piston slap.”

Oil Consumption Issues

-

Cylinder bores are honed with steel torque plates that are torqued with ARP2000® bolts to simulate cylinder bore distortion, which occurs after head assembly, ensuring correct bore roundness.

-

100% installation of oil pressure relief valve baffle on all 2007 and later applications to redirect oil into the pan (Standard from OE on 2011 and later vehicles).

Valve Guide Wear-Causing Oil Consumption

-

100% installation of nitrided valves to improve durability and reduce friction.

Lifter Noise for Gen IV Engines

-

Latest-design Active Fuel Management (AFM) lifters are installed to increase oil flow during start-up and reduce lifter noise (2005 – present).

Low Oil Pressure

- JASPER-remanufactured oil pump includes a more rigid spring, tighter clearance for backing plate flatness, and is tested for increased oil pressure and flow.

- 100% installation of the latest-design block oil galley plug to correct inconsistent oil flow and prevent low oil pressure.

- Hydraulically installed cam bearings provide precise alignment, eliminating distortion of the bearings for improved oil flow and pressure.

Broken Exhaust Manifold Bolts

- 100% NEW exhaust manifold bolts are included.

Runnability and Leaks

- Oil pump, oil pan, timing cover, and rear cover are installed.

- 100% live-run tested to ensure proper compression, vacuum, and oil pressure.

- VVT actuator and/or AFM solenoid function is tested where applicable.

- 100% black light tested to ensure no leaks.

DOD/AFM Delete

- JASPER offers DOD/AFM Delete as an option for the 5.3, 6.0, and 6.2 engines.

- DOD/AFM Delete will have a Non-DOD/AFM Cam, 16 standard lifters, and the LOMA plate is replaced with an early-style valley plate.

- DOD/AFM Delete option is 50 state compliant. (CARB E.O. D-391-1).

GM V8 Gen V 5.3

Value-Added Quality Improvements from JASPER

Issue / Concern:

Oil Consumption Issues (Piston & Rings)

JASPER Solution:

-

JASPER-designed pistons offer profiled ring lands for scuff resistance under load, increased strength to withstand higher combustion pressures, and improved stability to reduce blow-by.

-

100% use of graphite-coated pistons to help prevent scuffing and wear.

-

JASPER-designed pistons provide 5 X more oil drain back for better oil control

-

Larger 4.00 mm oil control ring assembly provides improved oil scraping when compared to OEM’s 3.00 mm.

-

Anodized crown and top land promotes better top ring seal and drastically reduces any top ring micro-welding.

Oil Consumption Issues

-

Cylinder bores are honed with steel torque plates that are torqued with hardened bolts to simulate cylinder bore distortion, which occurs after head assembly, ensuring correct bore cylindricity.

Main/Rod/Cam Bearing Wear

-

100% installation of a proprietary antifriction, wear-resistant polymer coating on all bearings to reduce wear on dry start-up and increase longevity.

Low Oil Pressure

-

Dual displacement oil pump is electronically and mechanically tested during the live-run test to verify operation and correct oil pressure.

-

Hydraulically installed cam bearings provide precise alignment, eliminating distortion of the bearings for improved oil flow and pressure.

Head Gasket Failure

-

JASPER installs a thicker, polytetrafluoroethylene (PTFE) coated Multi-layer Steel (MLS) head gasket to maintain OEM compression ratio.

-

Block and heads are resurfaced to a 50–150 Rz finish.

-

100% installation of NEW Torque-to-Yield head bolts.

Lifter Noise

-

Latest-design Active Fuel Management (AFM) lifters are installed to increase oil flow during start-up and reduce lifter noise (2005 – present).

Runability Issues and Leaks

- Oil pump, oil pan, timing cover, and rear cover are installed.

- 100% live-run tested to verify proper compression, vacuum, and oil pressure.

- VVT actuator and/or AFM solenoid function is tested where applicable.

- 100% black light leak tested to ensure the unit is leak-free.

DOD/AFM Delete

Additional JASPER® Benefits

- JASPER installs a fuel pump drive roller for proper high-pressure pump operation.

- JASPER includes a finishing gasket set for ease of installation.