ORDER NOW

CALL 800-827-7455 OR LOGIN TO YOUR ACCOUNT

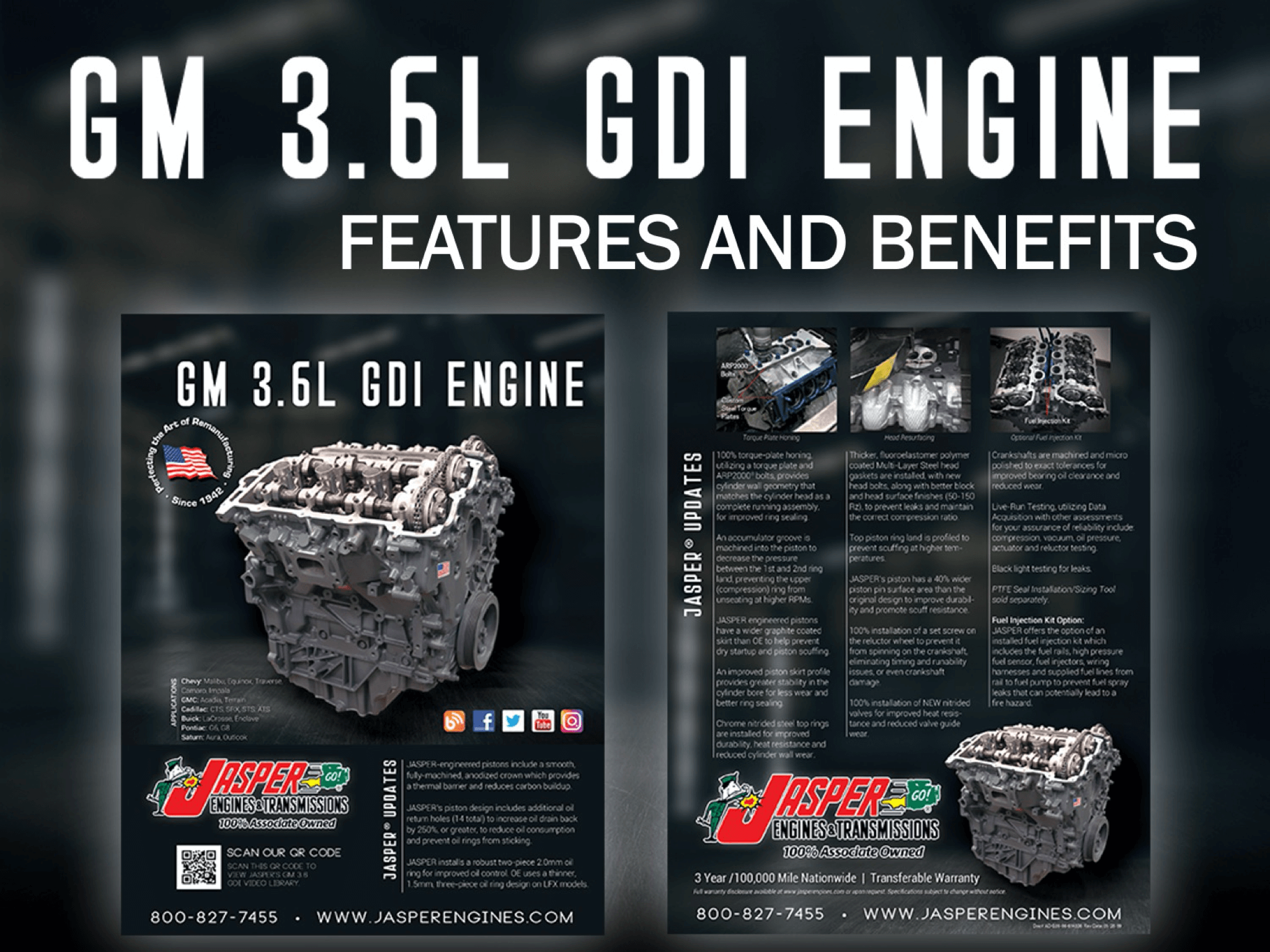

JASPER UPDATES

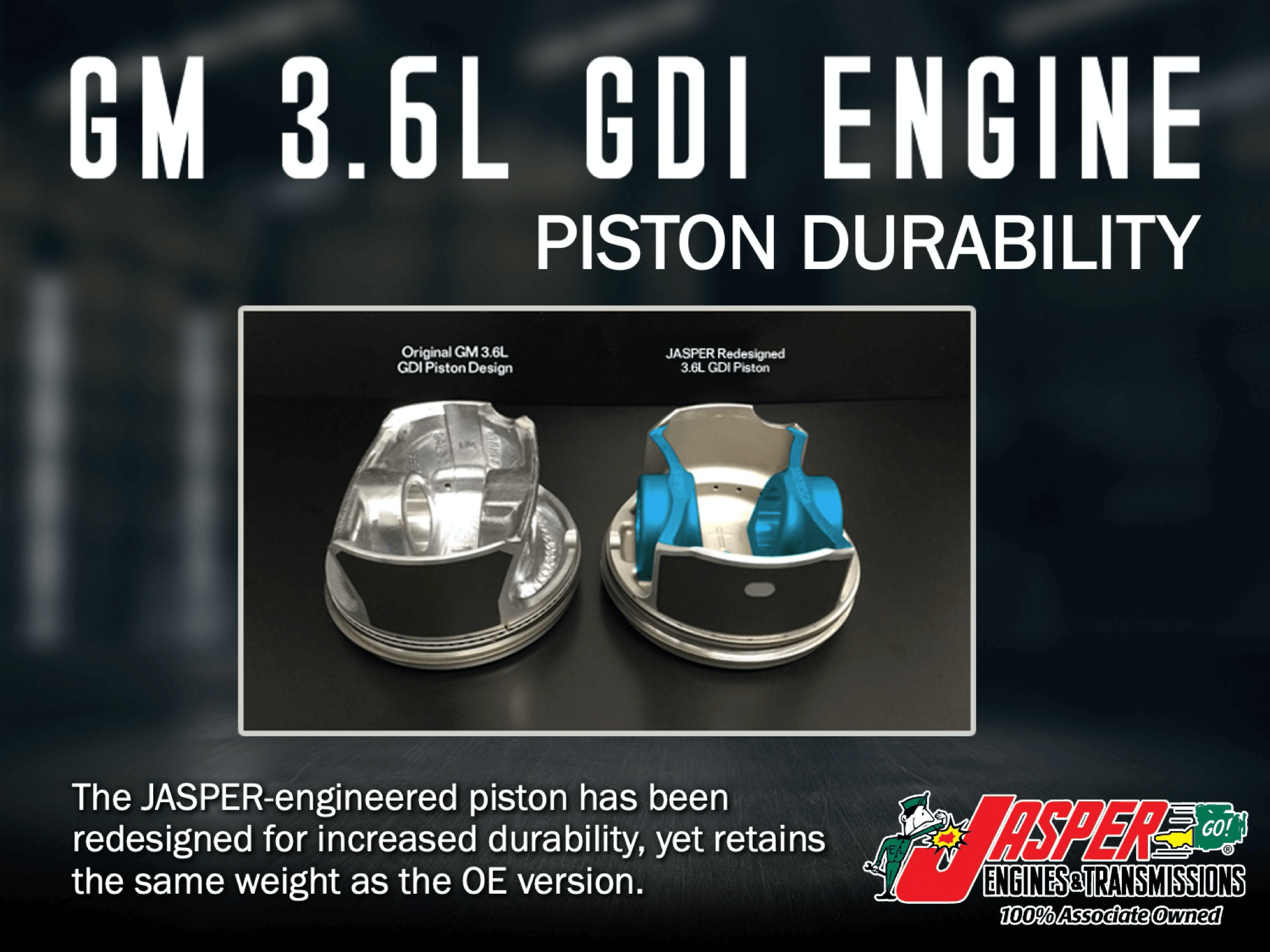

- JASPER-engineered pistons include a smooth, fully-machined, anodized crown which provides a thermal barrier and reduces carbon buildup.

- JASPER’s piston design includes additional oil return holes (14 total) to increase oil drain back by 250%, or greater, to reduce oil consumption and prevent oil rings from sticking.

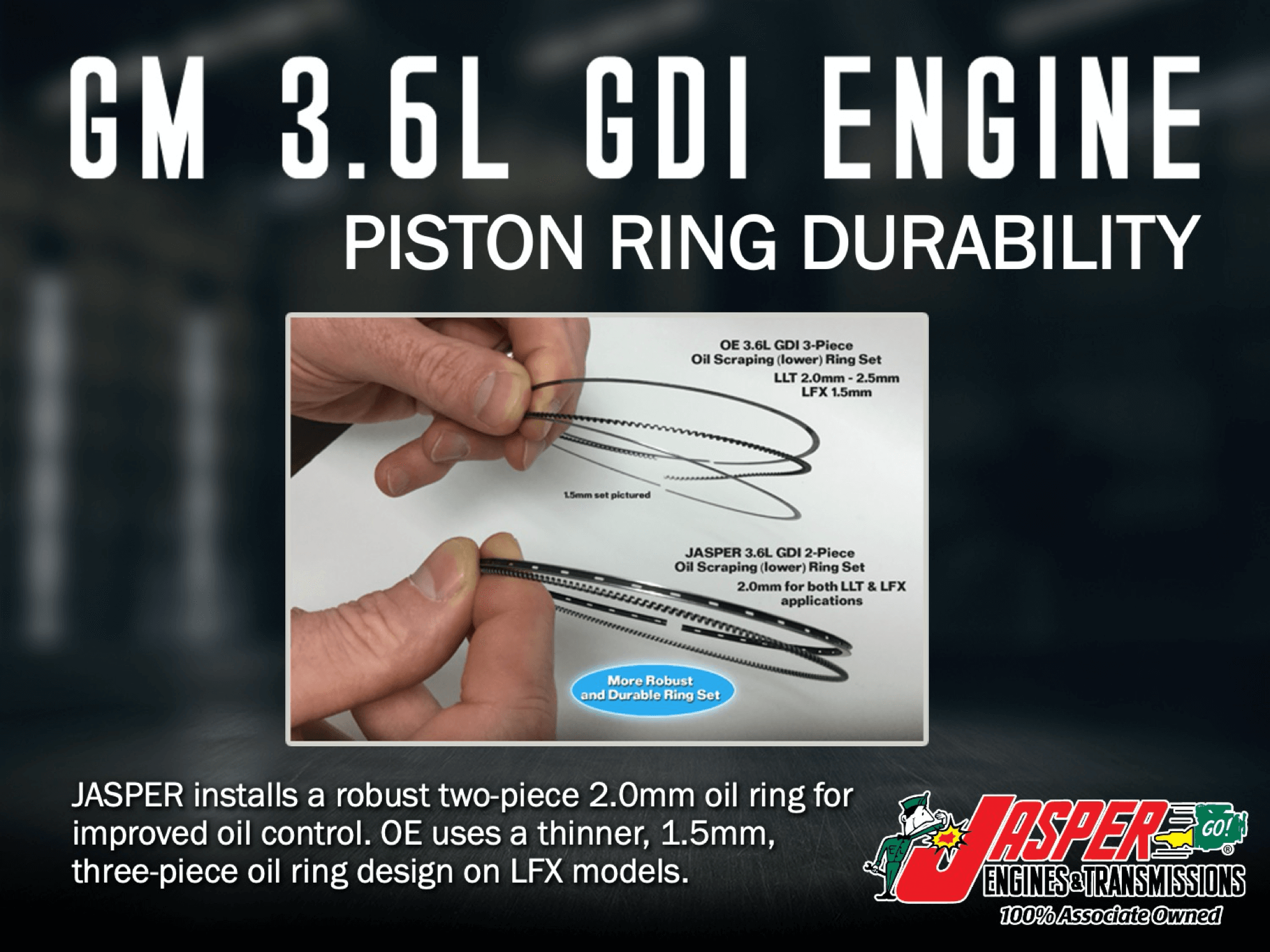

- JASPER installs a robust two-piece 2.0mm oil ring for improved oil control. OE uses a thinner, 1.5mm, three-piece oil ring design on LFX models.

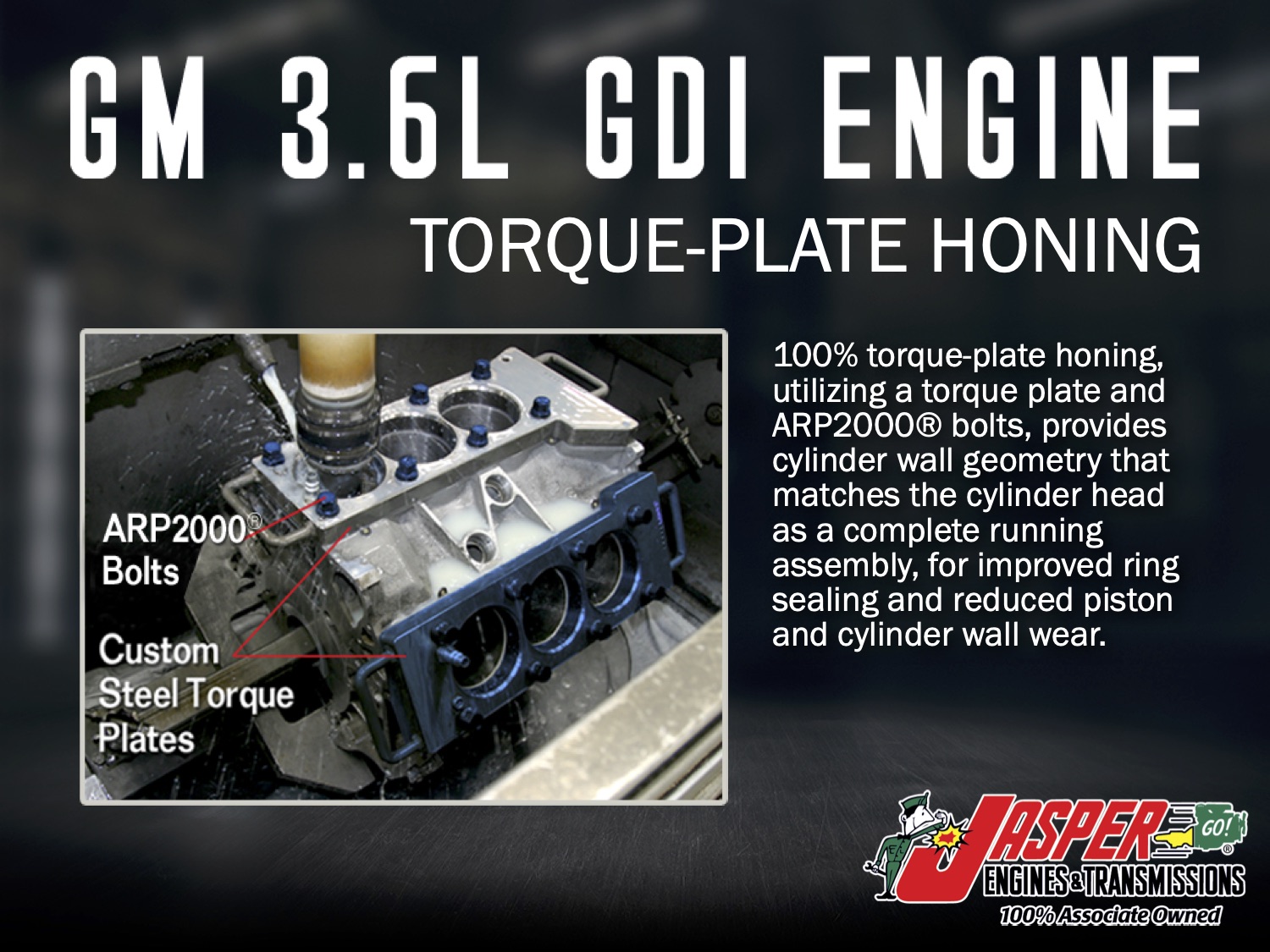

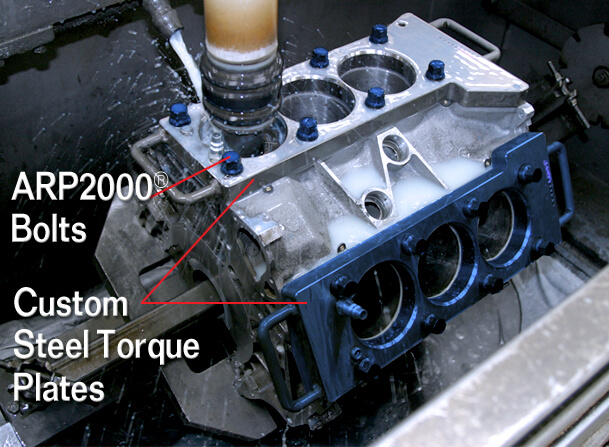

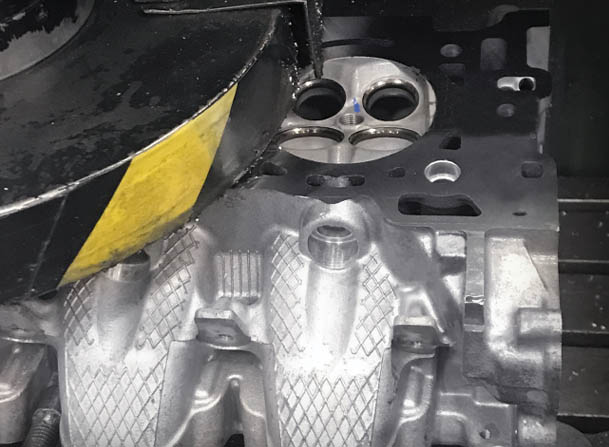

Torque Plate Honing

100% torque-plate honing, utilizing a torque plate and ARP2000® bolts, provides cylinder wall geometry that matches the cylinder head as a complete running assembly, for improved ring sealing.

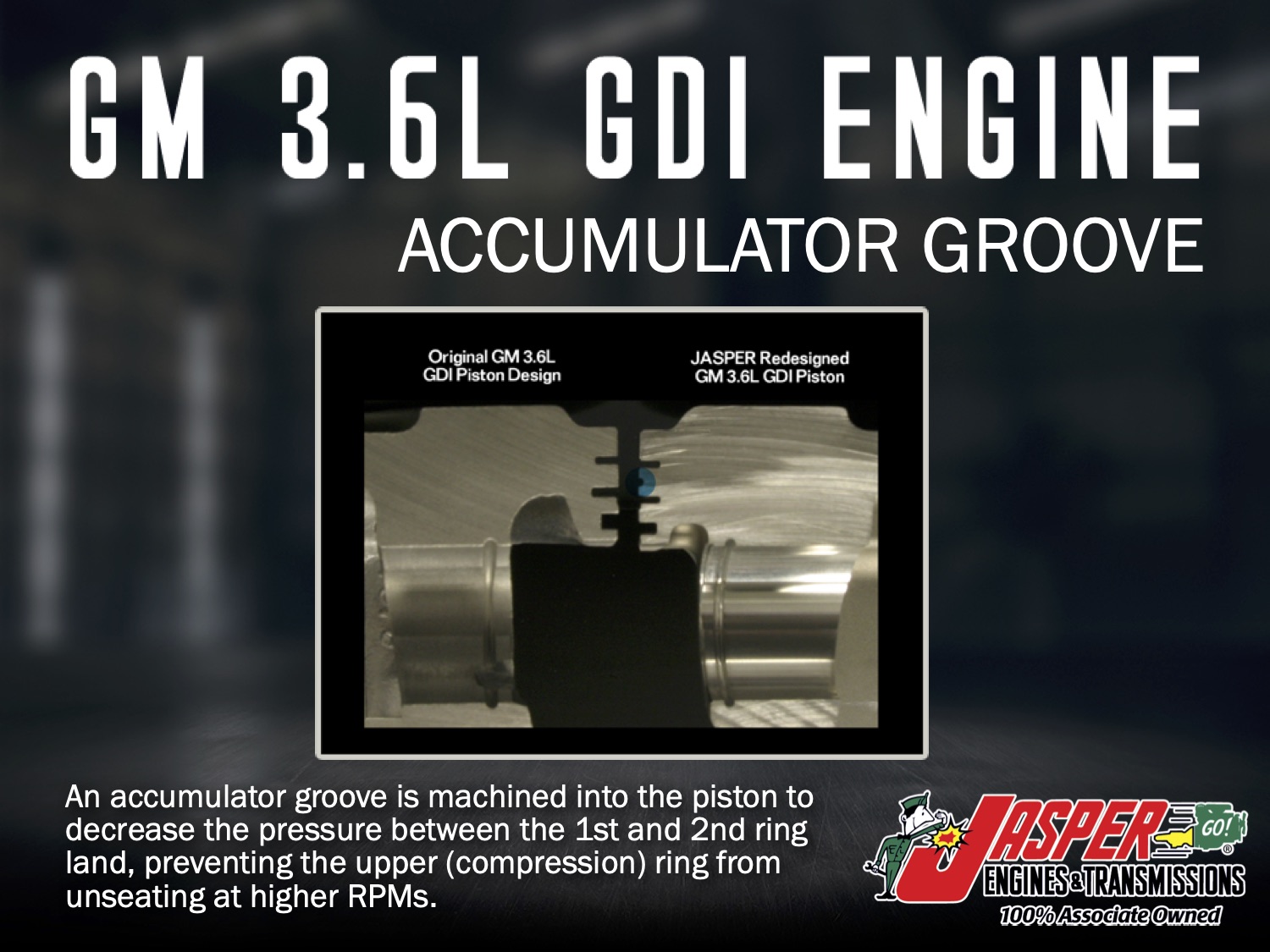

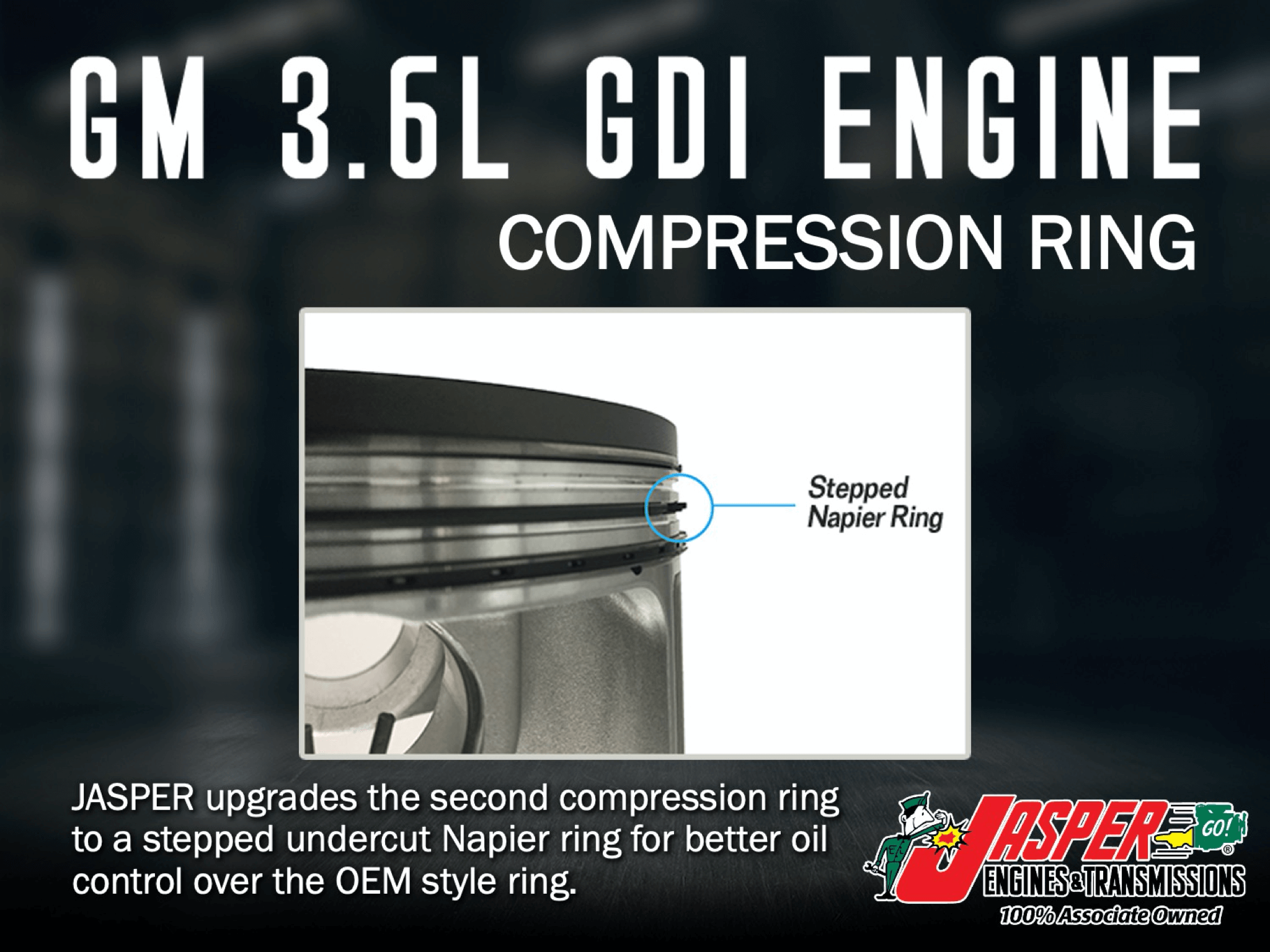

An accumulator groove is machined into the piston to decrease the pressure between the 1st and 2nd ring land, preventing the upper (compression) ring from unseating at higher RPMs.

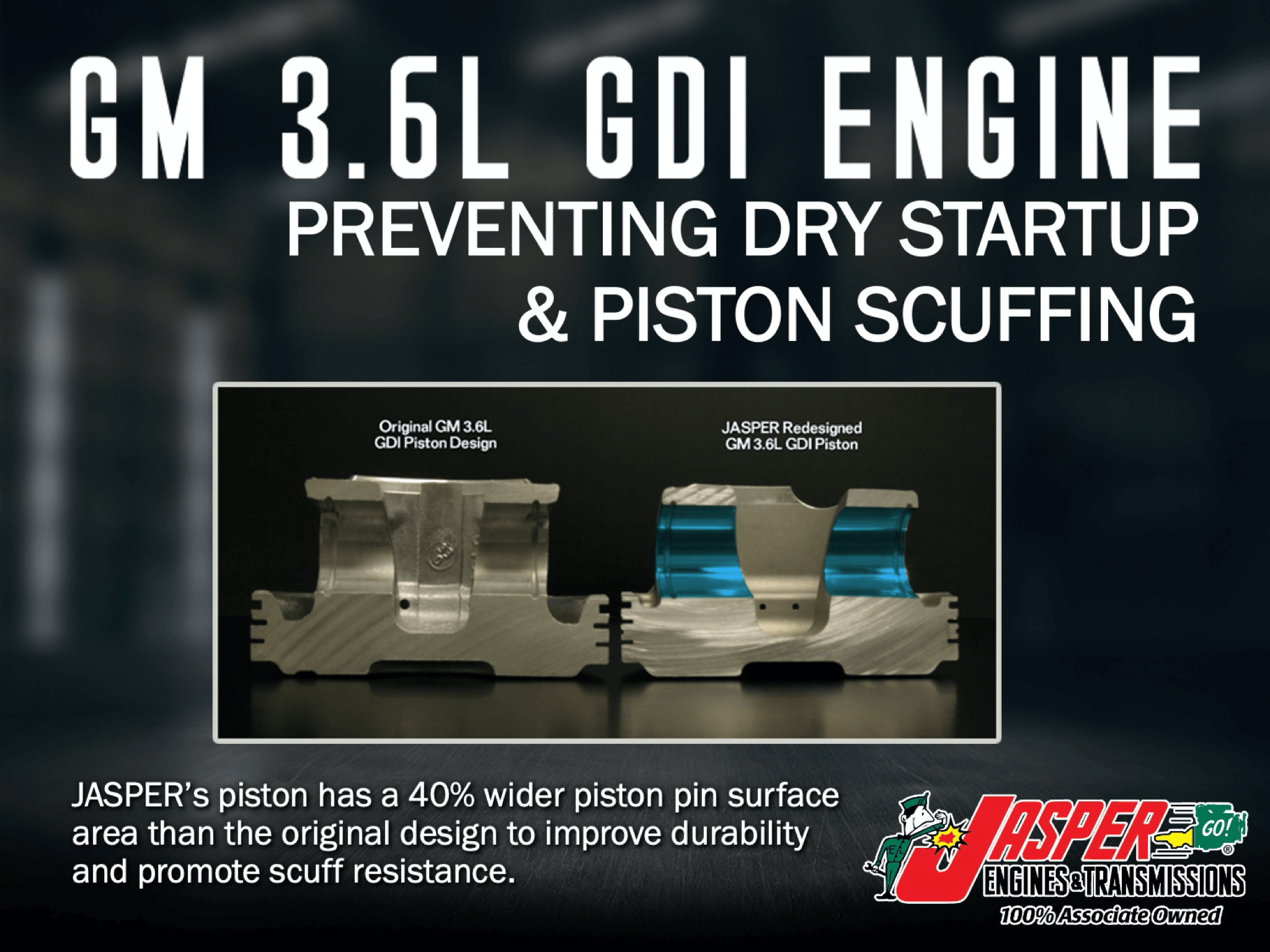

JASPER engineered pistons have a wider graphite coated skirt than OE to help prevent dry startup and piston scuffing.

An improved piston skirt profile provides greater stability in the cylinder bore for less wear and better ring sealing.

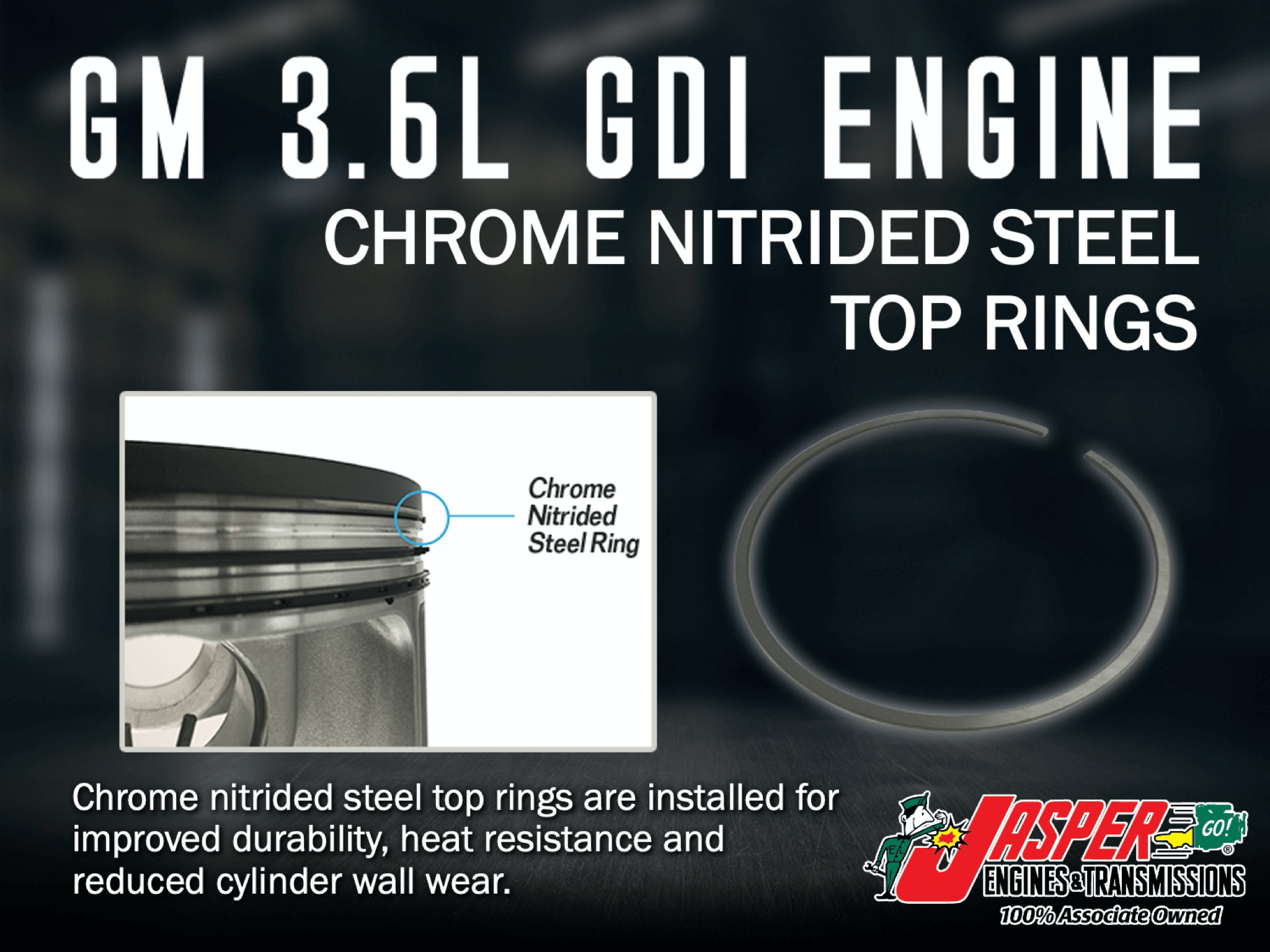

Chrome nitrided steel top rings are installed for improved durability, heat resistance, and reduced cylinder wall wear.

Head Resurfacing

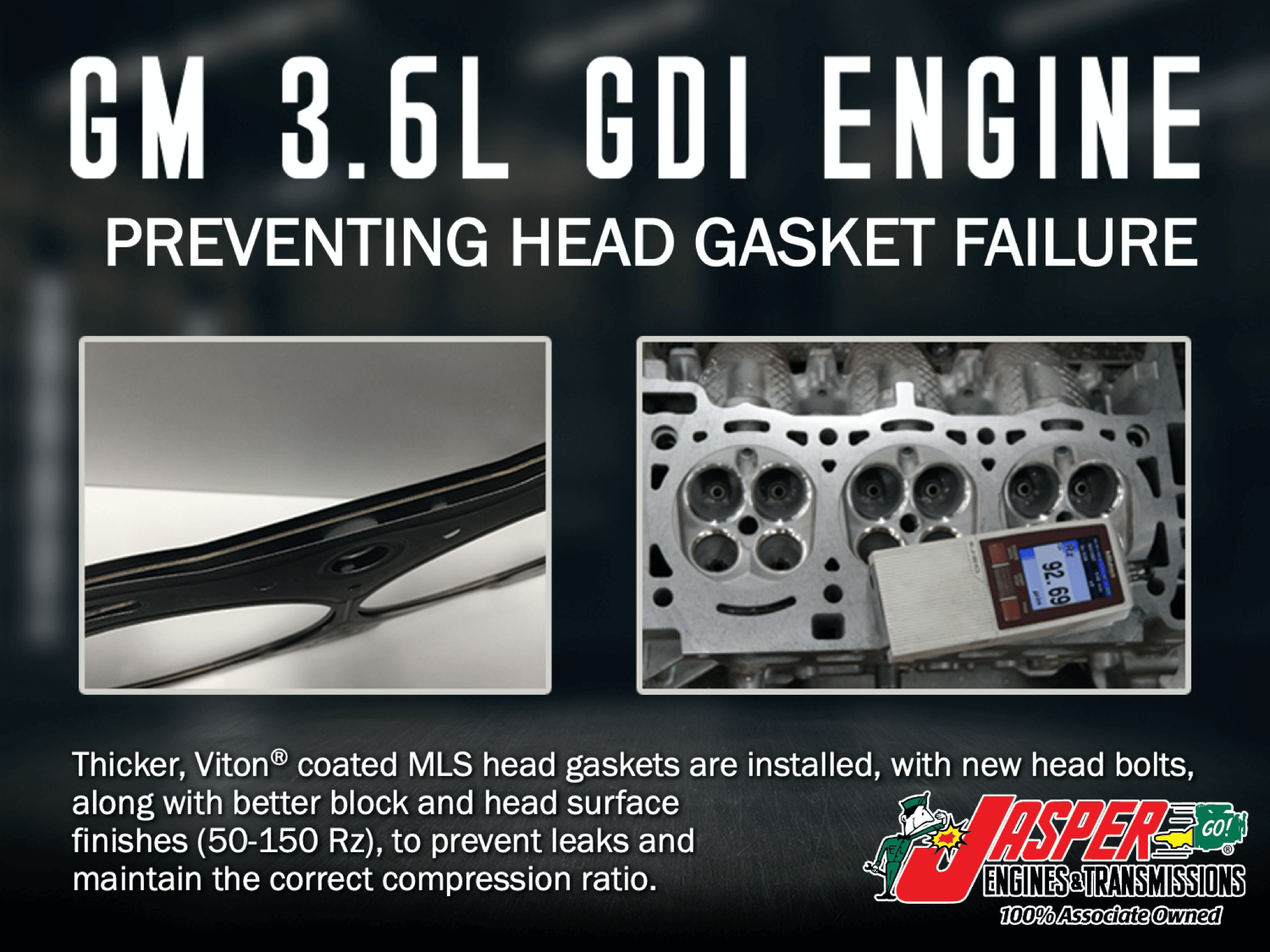

Thicker, fluoroelastomer polymer-coated Multi-Layer Steel head gaskets are installed, with new head bolts, along with better block and head surface finishes (50-150 Rz), to prevent leaks and maintain the correct compression ratio.

Top piston ring land is profiled to prevent scuffing at higher temperatures.

JASPER’s piston has a 40% wider piston pin surface area than the original design to improve durability and promote scuff resistance.

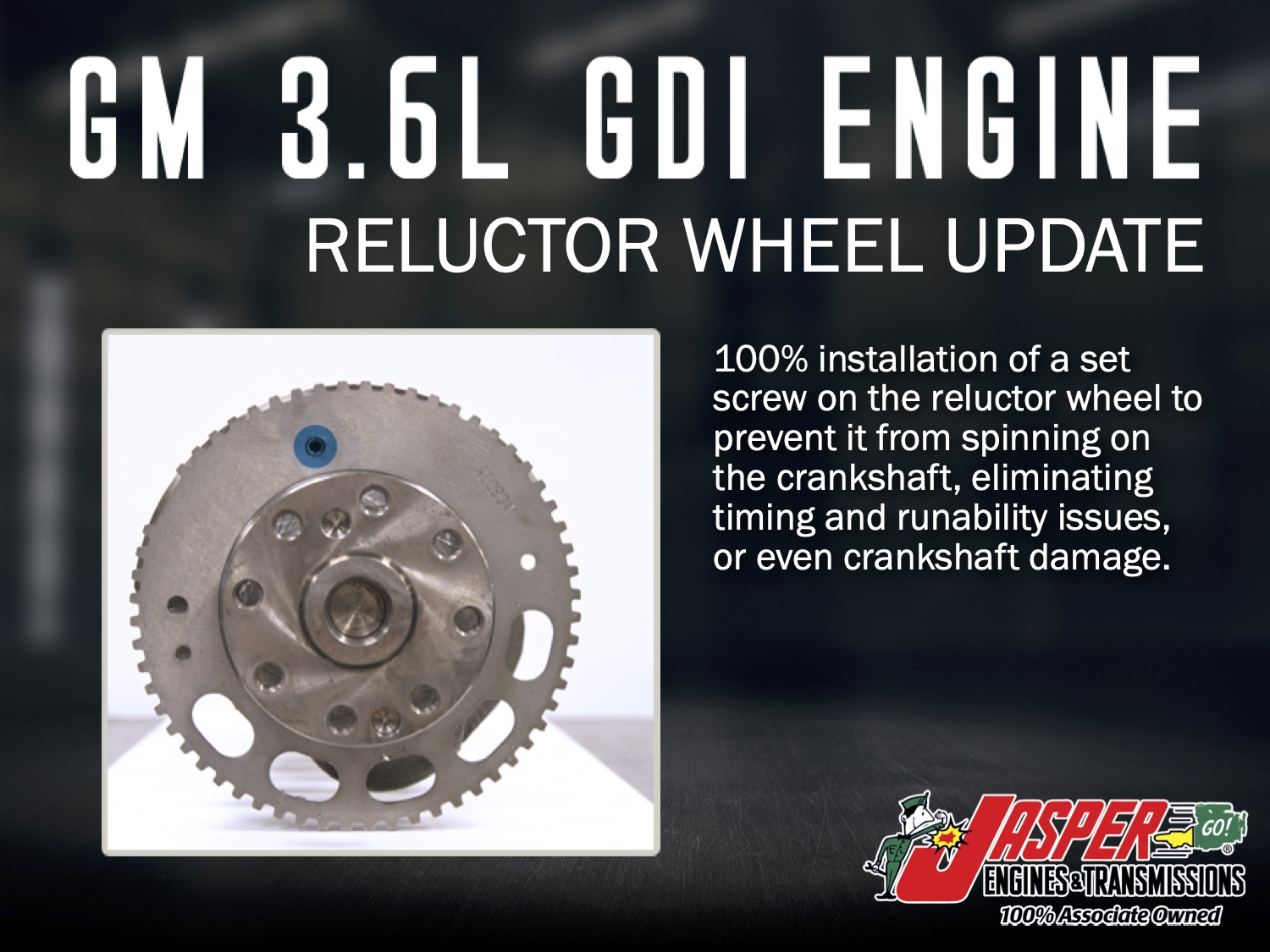

100% installation of a set screw on the reluctor wheel to prevent it from spinning on the crankshaft, eliminating timing and runability issues, or even crankshaft damage.

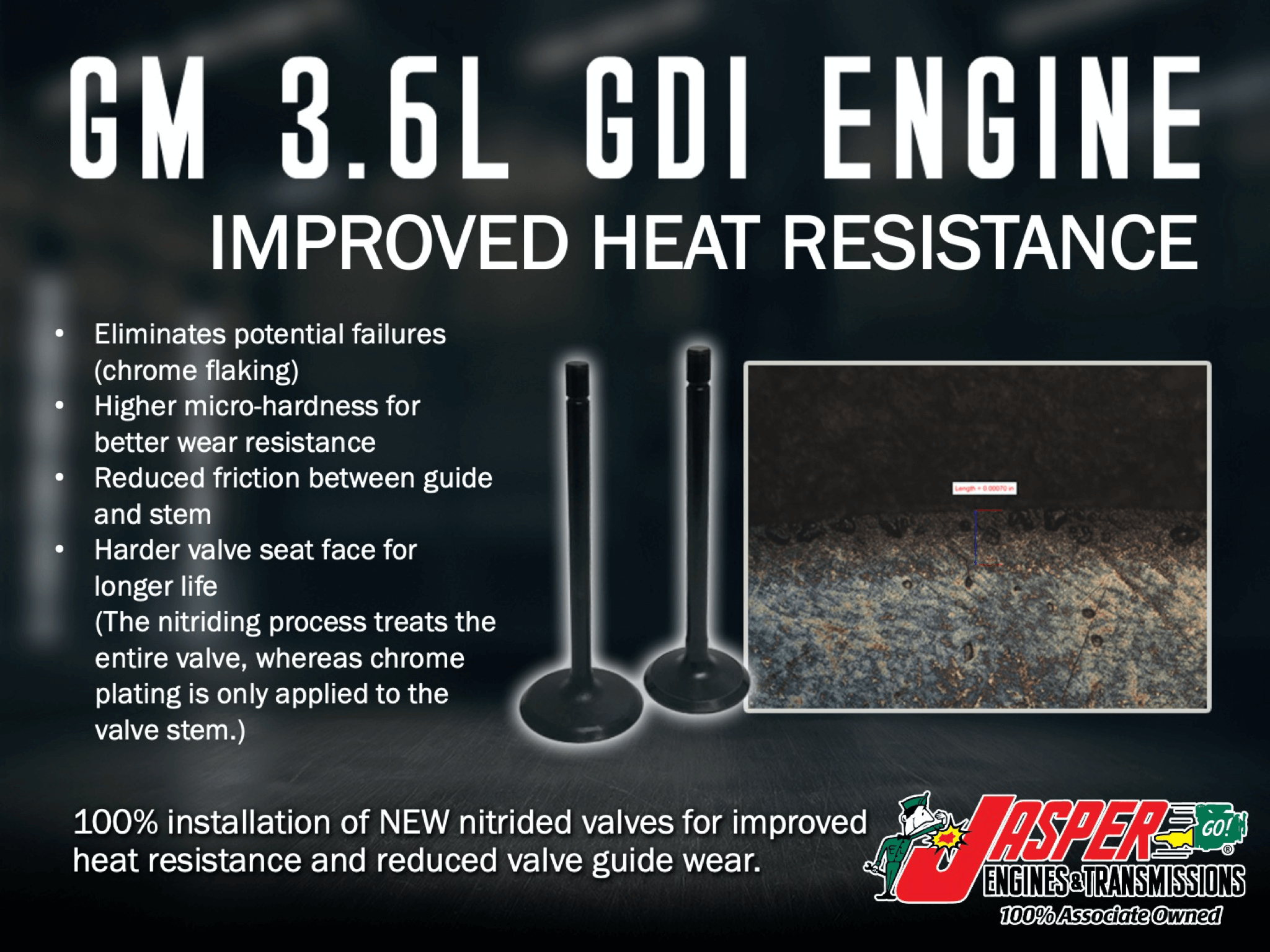

100% installation of NEW nitrided valves for improved heat resistance and reduced valve guide wear.

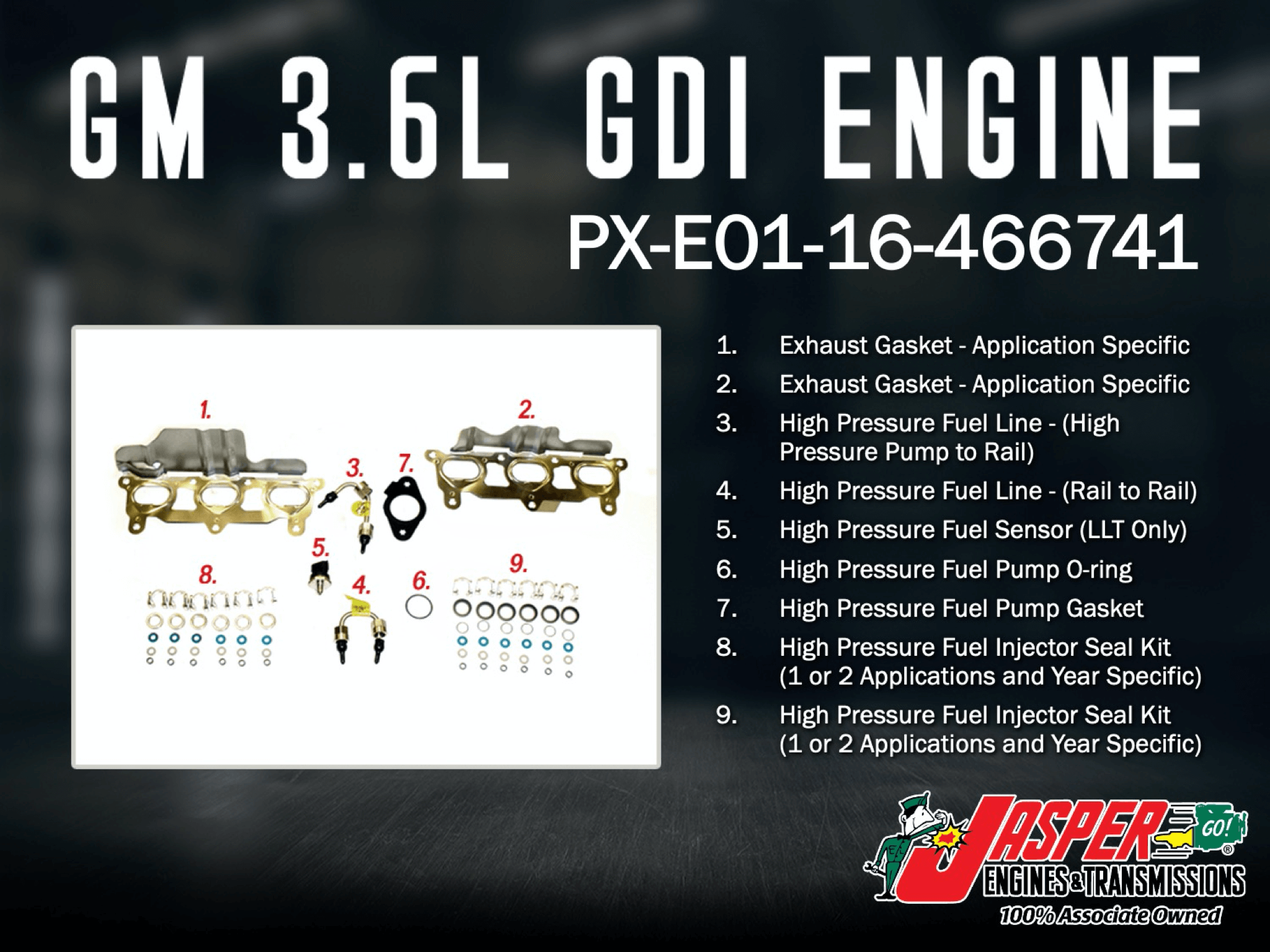

Optional Fuel Injection Kit

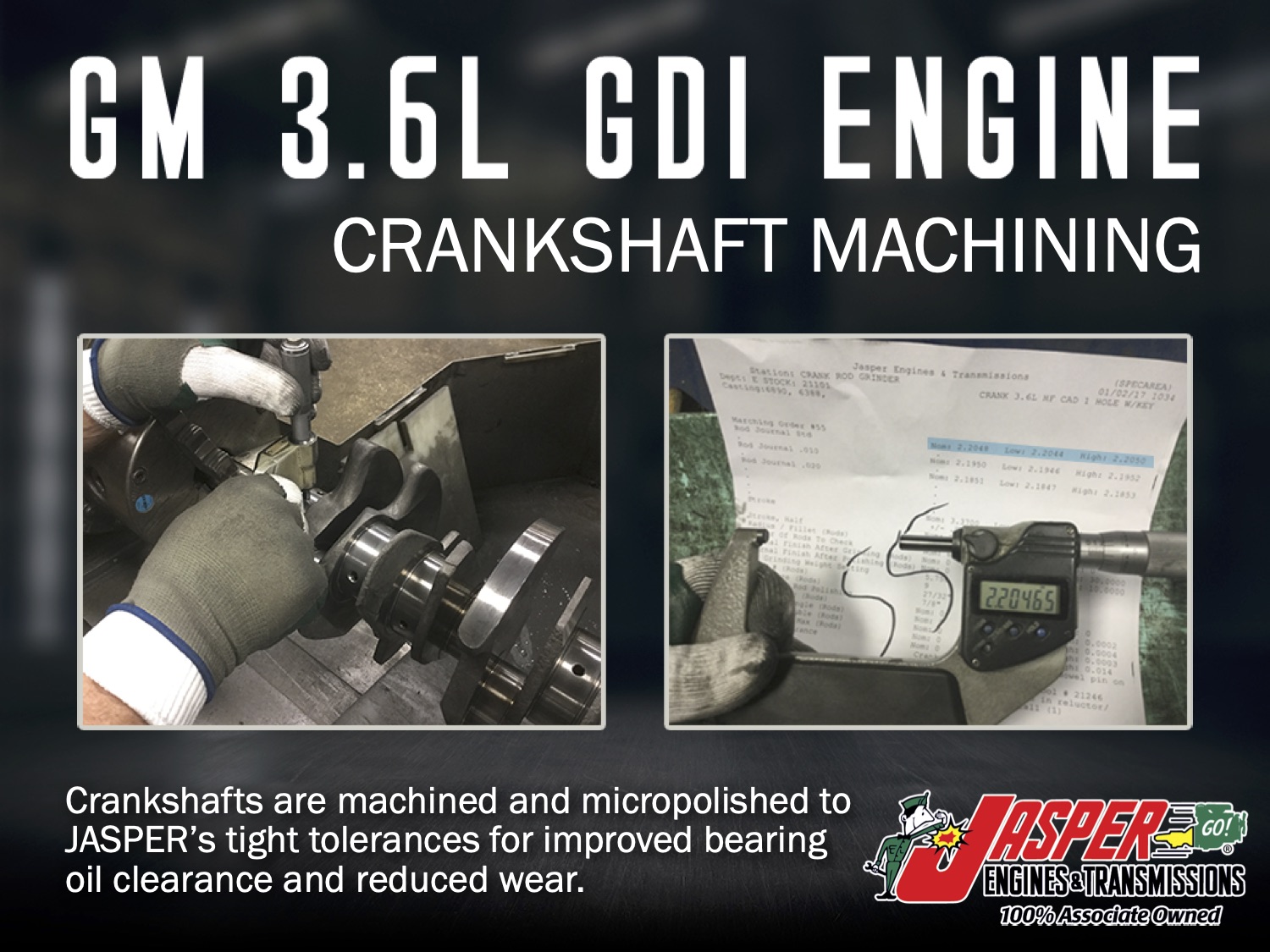

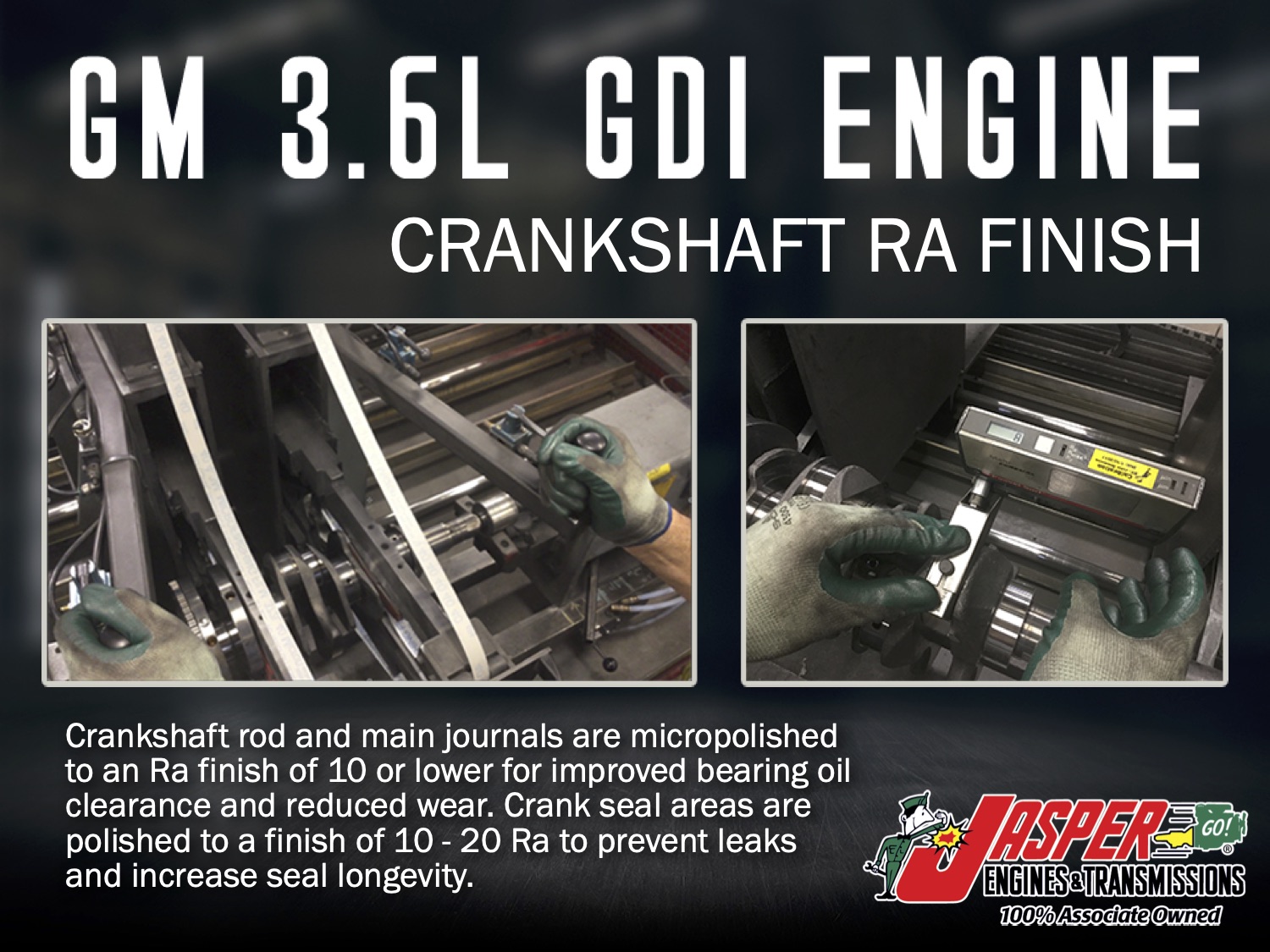

Crankshafts are machined and micropolished to exact tolerances for improved bearing oil clearance and reduced wear.

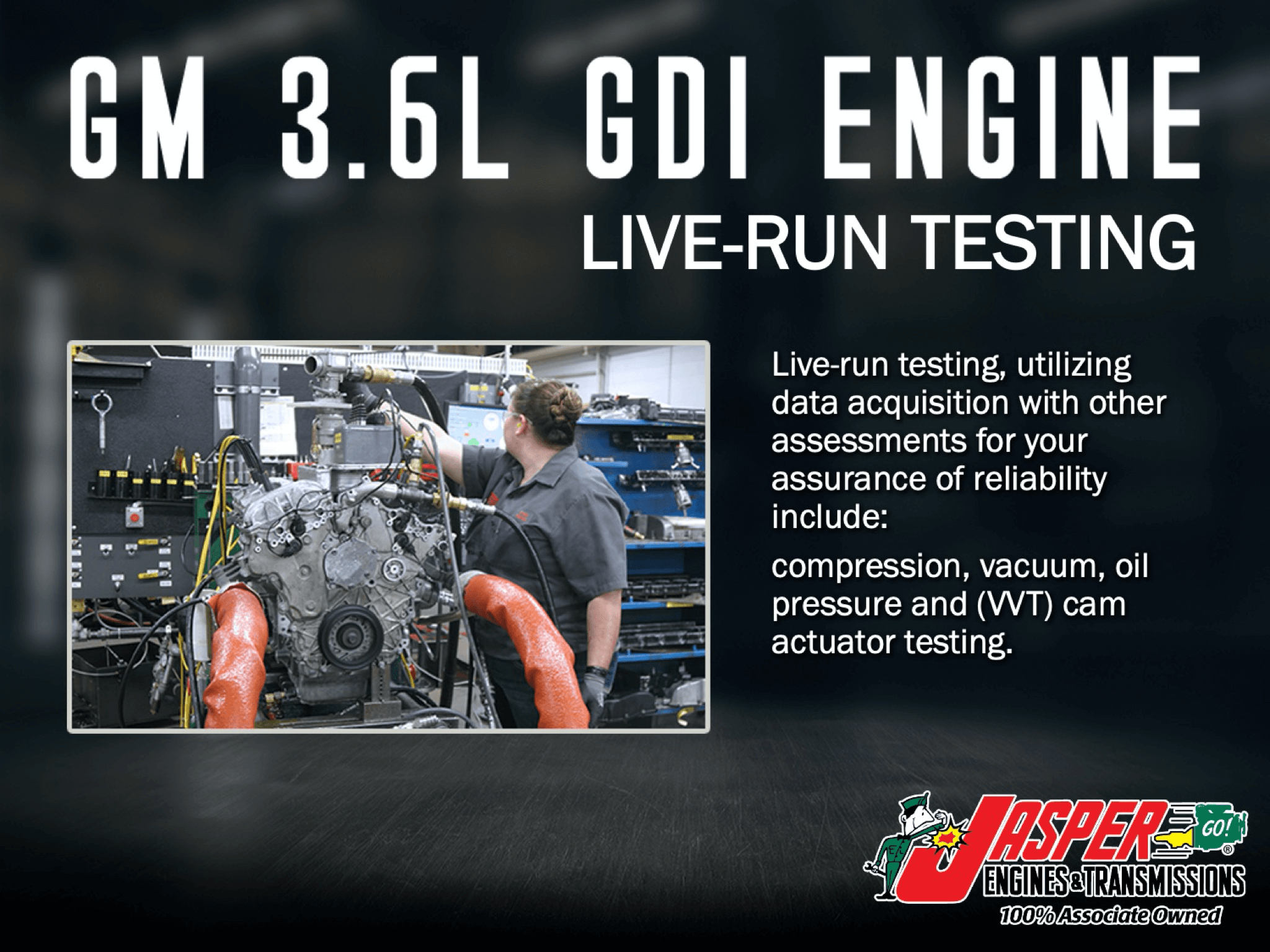

Live-Run Testing, utilizing Data Acquisition with other assessments for your assurance of reliability include compression, vacuum, oil pressure, actuator, and reluctor testing.

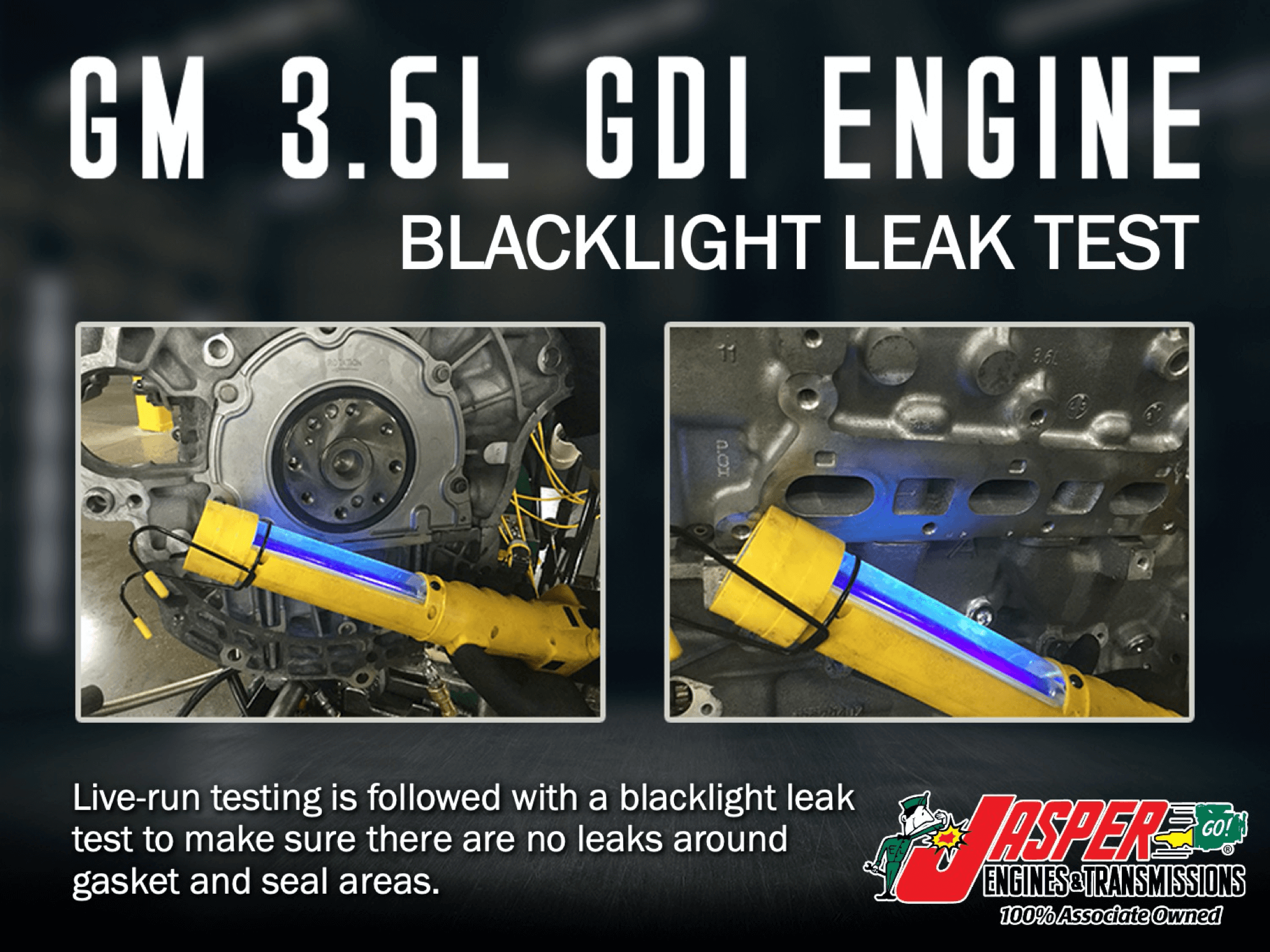

Blacklight testing for leaks.

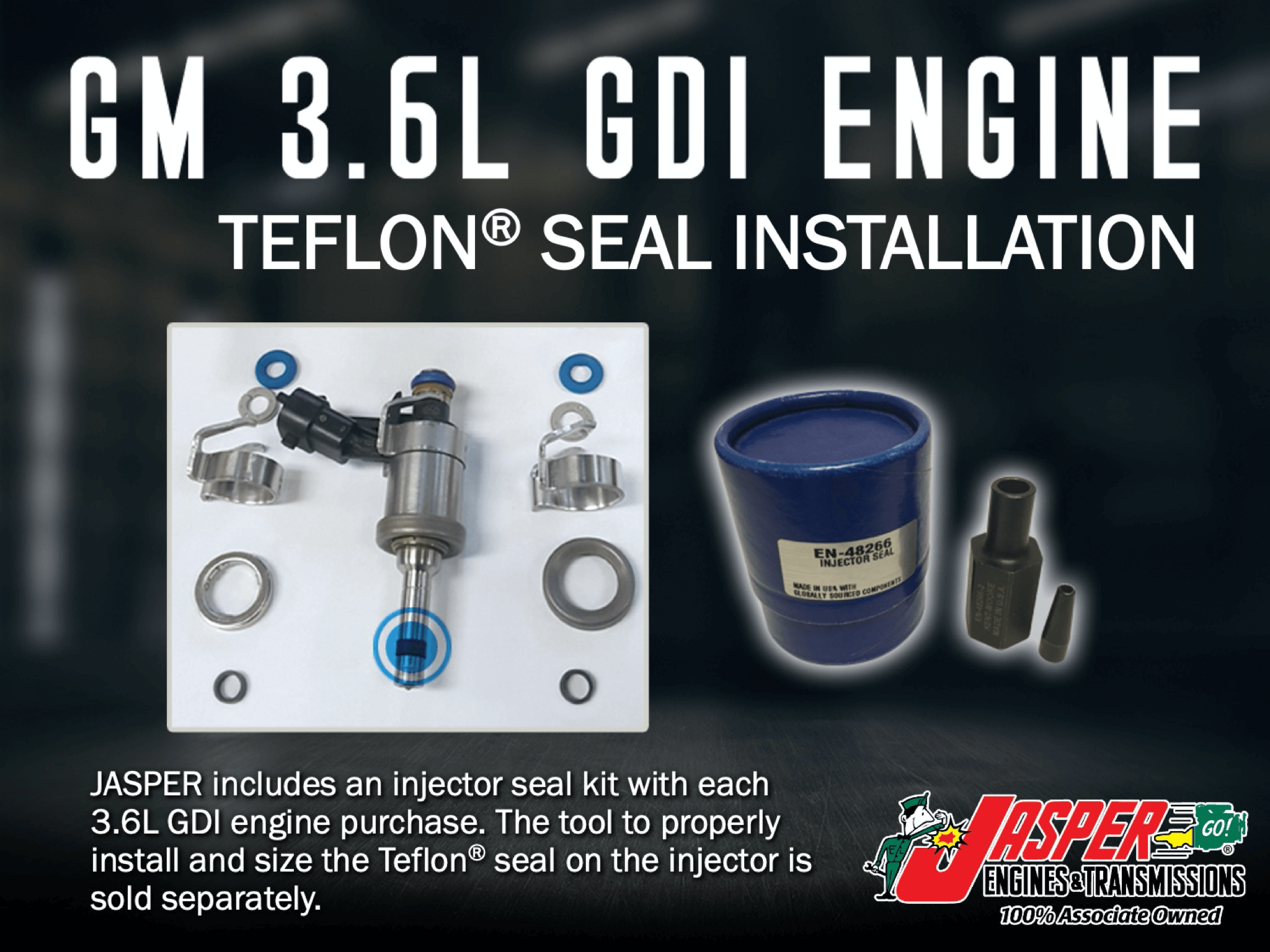

PTFE Seal Installation/Sizing Tool sold separately.

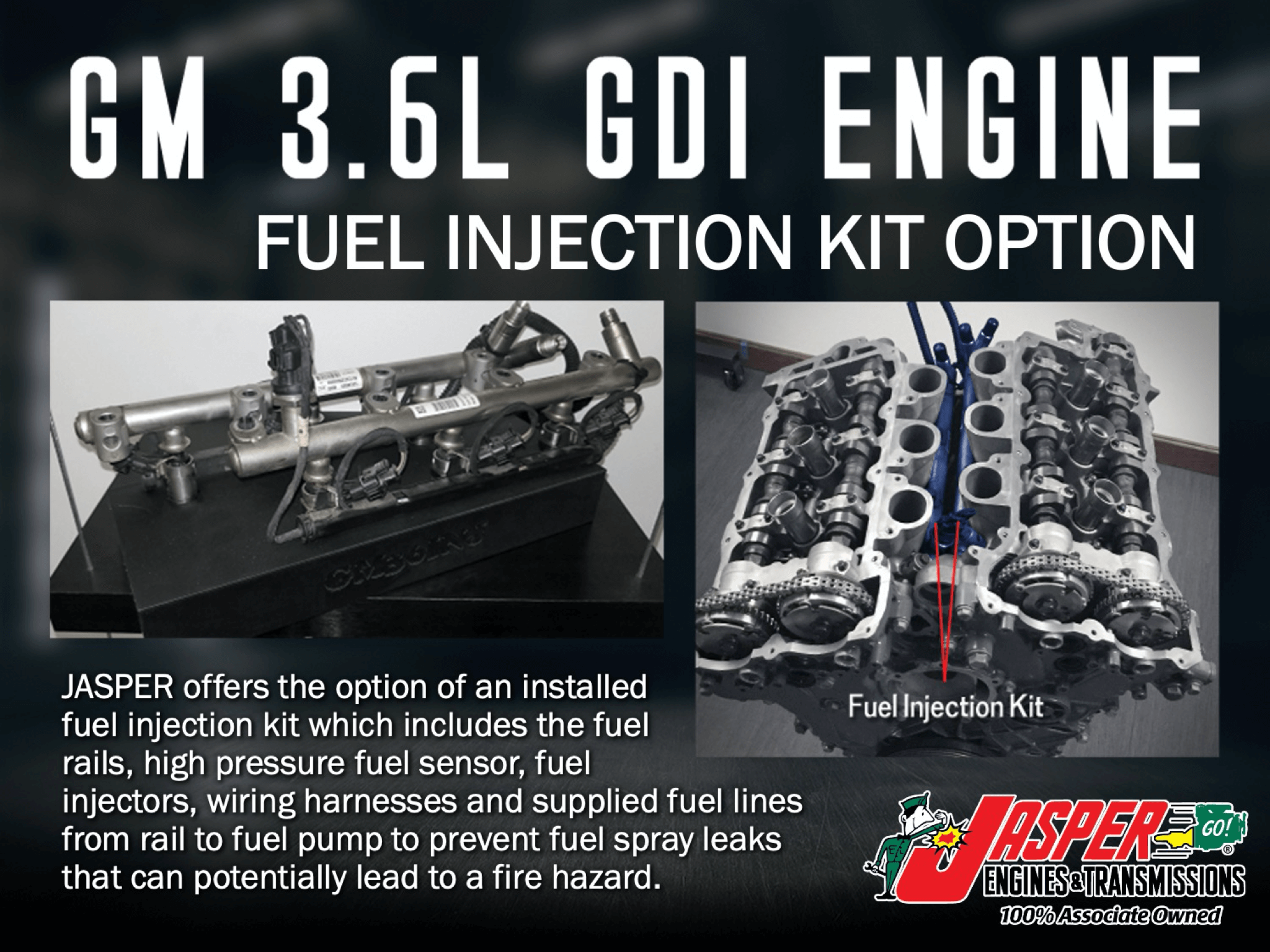

Fuel Injection Kit Option:

JASPER offers the option of an installed fuel injection kit which includes the fuel rails, high-pressure fuel sensor, fuel injectors, wiring harnesses, and supplied fuel lines from rail to fuel pump to prevent fuel spray leaks that can potentially lead to a fire hazard.

Product Videos

GM 3.6L GDI Reluctor Wheel Set Screw Update

GM 3.6L GDI Piston: Additional Oil Drainback Update

GM 3.6L GDI Piston: Anodized Crown Update

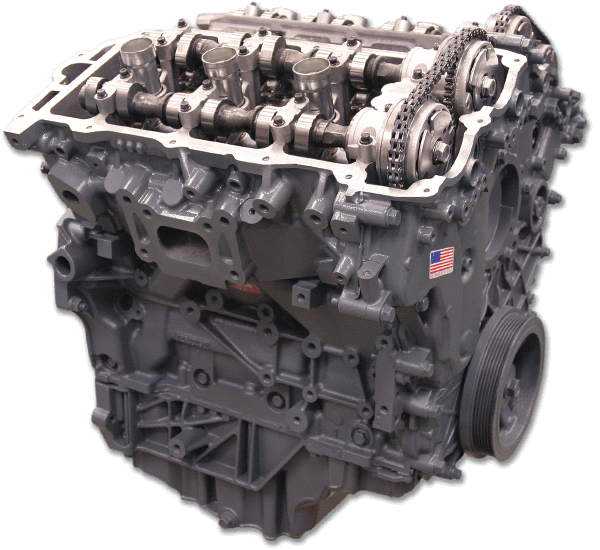

GM 3.6L GDI HIGH FEATURE

Value-Added Quality Improvements from JASPER

Issue / Concern:

Oil Consumption

JASPER Solution:

-

JASPER-engineered pistons include a smooth, fully-machined, anodized crown which provides a thermal barrier and reduces carbon buildup.

-

JASPER’s piston design includes additional oil return holes (14 total) to increase oil drain back by 250%, or greater, to reduce oil consumption and prevent oil rings from sticking.

-

JASPER installs a robust two-piece 2.0mm oil ring for improved oil control. OE uses a thinner, 1.5mm, three-piece design on LFX models.

-

Top ring land is profiled to prevent scuffing at higher temperatures.

-

Additional accumulator groove is machined into the piston to decrease the pressure between the 1st and 2nd ring land, preventing the upper (compression) ring from unseating at higher RPMs.

-

JASPER supplies an updated valve cover gasket in our JR set to assist in proper PCV operation and to help prevent oil consumption.

Dry Start-Up and Piston Scuffing

- 100% torque-plate honing of engine block, utilizing a torque plate and specially-designed ARP 2000® head bolts provides cylinder wall geometry that matches the cylinder head as a complete running assembly, for improved ring sealing.

- JASPER engineered pistons have a wider graphite coated skirt than OE to help prevent dry startup and piston scuffing.

- An improved piston skirt profile provides greater stability in the cylinder bore, reducing wear, providing better ring sealing.

- JASPER’s piston has a 40% wider piston pin surface area than the original design to improve durability and promote scuff resistance.

Spun Reluctor Wheel/Timing and Runability Issues

- 100% installation of a set screw on the reluctor wheel to prevent it from spinning on the crankshaft, eliminating timing/runability issues, or even crankshaft damage.

Cylinder Bore Wear

- Chrome nitrided steel top rings are installed for improved durability, heat resistance, and reduced cylinder wall wear.

Head Gasket Failure and Leaks

- Thicker, fluoroelastomer polymer (FPM) coated Multi-layer Steel (MLS) head gaskets are installed to ensure superior protection against gasket leakage. Our gasket is more robust to maintain the correct compression ratio.

- 100% installation of NEW head bolts to ensure even clamp load.

- Block and heads are resurfaced to a 50-150 Rz finish

Camshaft Noise / VVT Failure

- 100% installation of NEW camshaft thrust washers to prevent camshaft endplay and noise on early-design heads.

Low Oil Pressure/ Knocking

- Crankshafts are machined and micropolished to exact tolerances for improved bearing oil clearance and reduced wear.

Valve Guide Wear

- 100% installation of NEW nitrided valves for improved heat resistance and reduced valve guide wear.

Runability Issues and Fuel Leaks

- 100% live-run tested to verify proper compression, vacuum, and oil pressure.

- 100% tested intake and exhaust cam actuators to verify proper performance.

- 100% blacklight leak tested to ensure the unit is leak-free.

Fuel Injection

- JASPER offers the option of an installed fuel injection kit which includes the fuel rails, high-pressure fuel sensor, fuel injectors, wiring harnesses, and supplied fuel lines from rail to fuel pump to prevent fuel spray leaks that can potentially lead to a fire hazard.